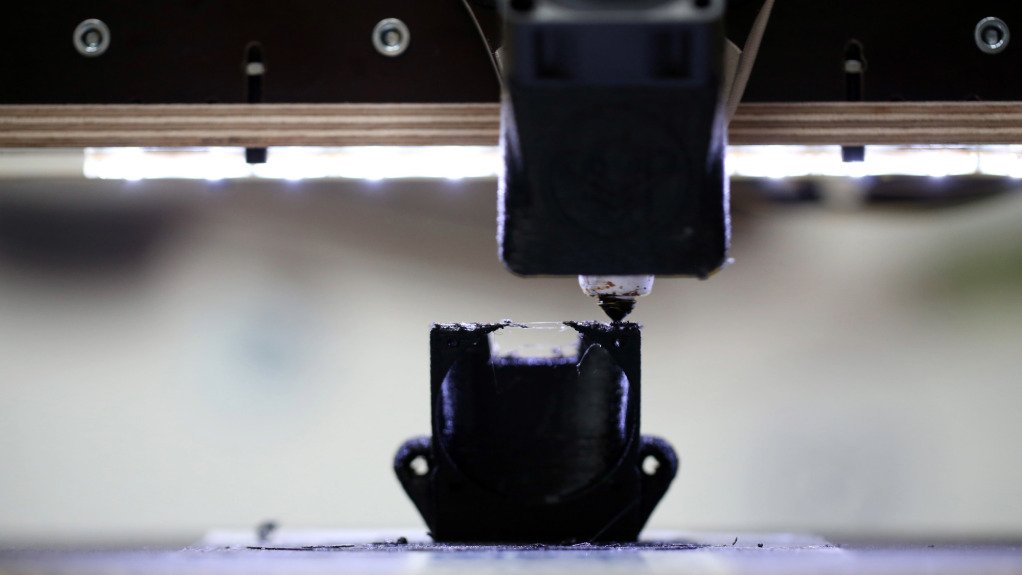

3D-printed heat exchanger prototypes in development

ADOPTING ADVANCED METHODS 3D printing enables greater design flexibility while also promising significantly reduced production times, ensuring high-performance heat exchangers tailored to demanding conditions

Photo by Bloomberg

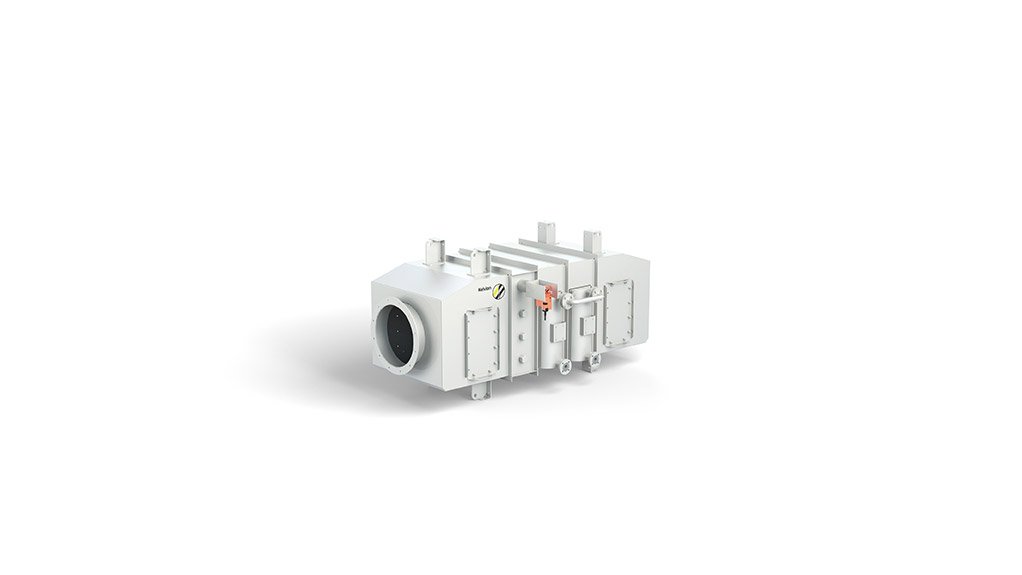

UPGRADE PENDING Through 3D topological optimisation and the use of next-generation materials, Kelvion is developing high-performance heat exchangers tailored to demanding conditions

As part of its partnership in Germany’s Economic Affairs and Climate Action Ministry-funded ESCO research project, heat exchange solutions provider Kelvion will develop “cutting-edge” three-dimensional (3D) printed heat exchanger prototypes using advanced materials specifically designed for supercritical CO2 systems, says Kelvion.

According to the company, this initiative reaffirms the company’s commitment to driving sustainable energy innovations.

Unlike conventional steam turbines, turbomachines using supercritical CO2 are more compact and require highly efficient heat recovery through innovative heat exchangers. The unique properties of supercritical CO2 necessitate precise aerodynamic optimisation, advanced sealing and bearing technologies, as well as materials capable of withstanding extreme pressures and temperatures.

Through 3D topological optimisation and the use of next- generation materials, Kelvion is developing high-performance heat exchangers tailored to these demanding conditions.

The adoption of 3D printing enables greater design flexibility while also promising significantly reduced production times compared with traditional manufacturing methods. Once proven, these advancements will “pave the way” for broad commercialisation and industry adoption, says Kelvion.

Transforming Energy-Intensive Industries

The global energy landscape is evolving rapidly, driven by the need for more efficient, flexible and sustainable power generation. As energy demands increase, dispatchable generation units and innovative energy storage systems are critical to ensuring supply security and system stability.

Kelvion notes that water-steam cycles are well-established and widely used in power generation, however, the energy transition is driving increased interest in alternative technologies.

In this context, supercritical CO2 power cycles have emerged as a “ground-breaking alternative” to traditional water-steam cycles, offering significant advantages in efficiency and system compactness.

While demand for supercritical CO2 systems has historically been limited, especially in Europe, the growing need for higher efficiency and reduced environmental impact is shifting this dynamic.

Supercritical CO2 power cycles offer several advantages, including higher efficiency compared with conventional systems, and smaller, more compact components, which simplify system design while reducing costs and water consumption.

These benefits position supercritical CO2 technology as a transformative solution for sectors such as waste heat recovery, geothermal energy, solar thermal applications and thermal energy storage systems.

ESCO Involvement

The ESCO research project aims to optimises CO2 cycle technology for industrial applications.

Owing to the special properties of CO2 above the critical point of 31ºC, or 73.8 bar, there are advantages to using it in thermodynamic cycle processes, Kelvion states. These cyclic processes achieve higher efficiencies and a significant reduction in the size and complexity of the individual components.

As a result, heat sources that could not previously be used economically show potential for stable energy supply. However, research is required before commercialisation can progress. The main challenges for supercritical CO2 turbomachines include heat recovery, aerodynamic optimisation, new sealing and bearing technologies, material suitability and limited operational experience with control systems.

“Kelvion’s involvement in the ESCO project reflects our commitment to advancing energy technology and sustainability,” says Kelvion research and innovation VP Stefan Ziegler.

“By collaborating with leading industry partners, we aim to redefine heat exchanger design, establish new industry standards, and drive transformative change in global energy systems. Together, we are contributing to a more efficient, sustainable energy future.”

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation